Cannes Lions

AIZOME ULTRA™ – An innovative method to create textiles with lasting health benefits.

SERVICEPLAN, Munchen / AIZOME / 2023

Awards:

Overview

Entries

Credits

Overview

Background

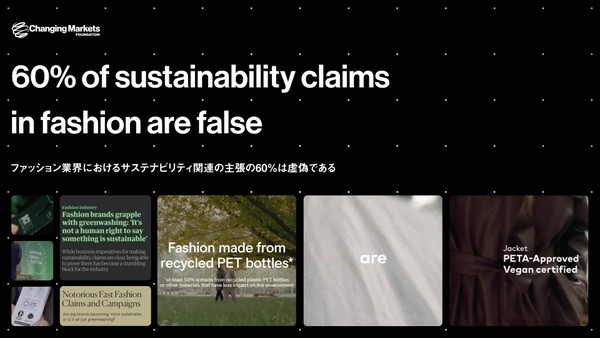

The 1500+ synthetic chemicals used in textile dyeing harm workers, wearers and the environment. While the industry slowly changes, greenwashing prevails.

Plants have long been used in dyeing, but without binding chemicals, color and health benefits fade quickly. This makes it unsuitable for mass production.

Idea

AIZOME ULTRA™ is an innovative method to create textiles with lasting health benefits.

It begins with only water, medicinal plants, and cotton. But instead of synthetic chemicals, it uses a physical trick: ultrasound sets the plant particles in motion at a custom frequency of 52.5kHz, binding them to the fiber permanently. And with them, their color and health benefits.

Strategy

While the textile and fashion industry are invested in innovations that reduce or neutralise harm, there is need for a new outlook: AIZOME ULTRA™ is a simple innovation that modernises traditional Japanese plant-based dyeing with ultrasound and ensures that every step of the process is transparent and even beneficial.

The medicinal plants used transfer their unique benefits deep into the textiles, and keep the wastewater free from toxic chemicals – reused in the irrigation of the same plants. Thus, creating a valuable and sustainable loop.

Execution

Implementation

AIZOME ULTRA™ begins only water, medicinal plants, and cotton. But instead of synthetic chemicals, it uses a physical trick: ultrasound sets the plant particles in motion at a custom frequency of 52.5kHz, binding them to the fiber permanently. And with them, their color and health benefits.

The actual dyeing process takes between 60-90 minutes, with repeated sonification. As a whole, monitoring 100% organic quality from farm to finish, manufacturing can take about 1 year.

Timeline

2015 - Michel May and Misa Muto began experimenting with chemical-free dyeing methods.

2016 - The ultrasonic dyeing process AIZOME ULTRA™ is patented.

2017 - AIZOME is founded.

2019 - Mass-production fabrics are commercially released.

2021 - Three additional colors are introduced.

2022 - First partnerships within the healthcare sector secured.

2023 - Partnerships with healthcare, fashion, and educational institutes are underway.

Similar Campaigns

6 items