Cannes Lions

AIZOME ULTRA™ – Healthcare you can wear

SERVICEPLAN, Munchen / AIZOME / 2023

Overview

Entries

Credits

OVERVIEW

Background

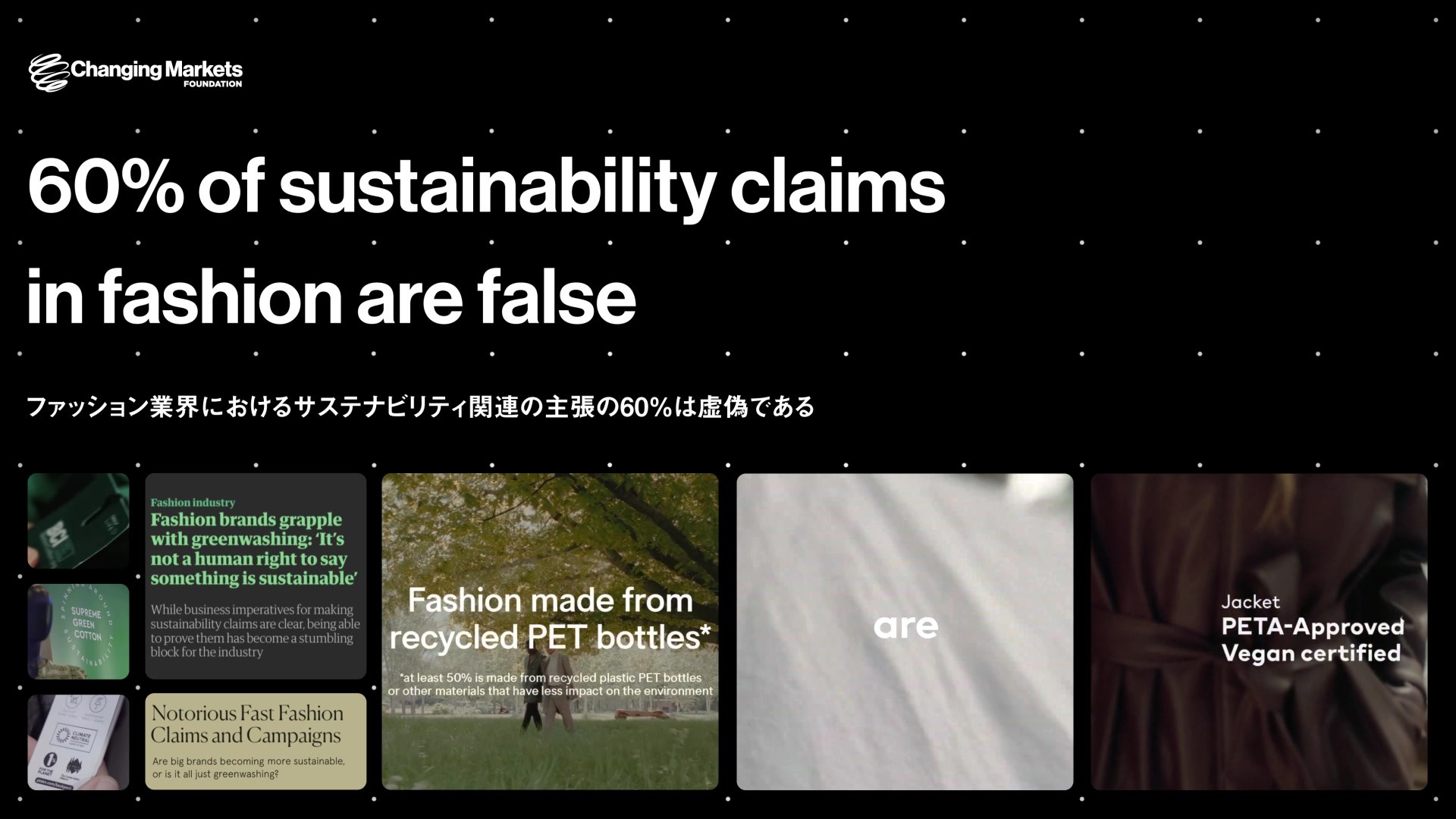

The 1500+ synthetic chemicals used in textile dyeing harm workers, wearers and the environment. While the industry slowly changes, greenwashing prevails.

Medicinal plants have long been used in dyeing, but without binding chemicals, color and health benefits, such as hydrating, anti-inflammatory or stress reducing effects, fade quickly. This has made medicinal plant-based dyeing unsuitable for mass production.

Idea

AIZOME ULTRA™ solves this. It begins with only water, medicinal plants, and cotton. But instead of synthetic chemicals, it uses a physical trick: ultrasound sets the plant particles in motion at a custom frequency of precisely 52.5kHz, binding them to the fiber permanently – along with their color and health benefits.

Strategy

The goal was to develop an alternative to synthetic chemicals in textile dyeing, that is simple, scalable, and sustainable. No complicated apparatus, no greenwashing. The combination of traditional plant-based dyeing with ultrasonication emerged as solution. Through long tests, the optimal frequency was determined.

2015 – Michel May and Misa Muto began experimenting with chemical-free dyeing methods.

2016 – The ultrasonic dyeing process AIZOME ULTRA™ is patented.

2017 – AIZOME is founded.

2019 – Mass-production fabrics are commercially released.

2021 – Three additional colors are introduced.

2023 – Partnerships with healthcare, fashion, and educational institutes are underway.

Execution

While eliminating chemicals in the process, AIZOME ULTRA™ now gives wearables healing properties: bedsheets can help heal wounds, t-shirts reduce stress, underwear ease menstrual pain. The possibilities are endless.

AIZOME ULTRA™ is patented and recognized by several renowned international organizations and institutions such as the University of Cambridge. It is also recognized by the National Eczema Association as an innovation that improves the quality of life for people with sensitive skin.

Outcome

AIZOME ULTRA™ is simple, scalable, and sustainable. AIZOME even uses the wastewater to fertilize their fields. So far, more than 3,000 tons of fabric have been produced, benefiting 2.4 million people. To date, AIZOME has received substantial investments and media attention across the globe. Textiles produced with AIZOME ULTRA™ are used by consumers and healthcare facilities in Europe and the US.

Partnerships with fashion brands, as well as cosmetics producers are underway and will be announced publicly later this year.

Similar Campaigns

6 items